Eiffage deploys its expertise and know-how in a wide range of activities

Our self-delivery capacity allows us to develop turnkey, tailored project solutions to answer the needs of our diverse client base.

- Civil engineering

We are an internationally recognised player in the civil engineering sectors, with experience ranging from the most basic projects to the immensely complex, such as road, rail, bridges, tunnel, dams, earthworks…

- Marine

We have the capacity to carry out offshore and inland waterway works. Our teams are able to handle marine and river projects through their extensive technical expertise.

- Energy

We have broad experience with offshore wind project management and implementation, from the jacket construction and transport to site right up until installation. We also have vast nuclear civil engineering and industrial expertise.

Civil engineering projects

-

High Speed 2 (HS2)

United Kingdom - London to Birmingham

High Speed 2 (HS2)

The future HS2 high speed rail link built as part of a joint venture involving Eiffage, Kier, Ferrovial Construction and BAM Nuttall (EKFB) will serve the north of the United Kingdom. All four partners bring specialist expertise in the design, construction, operation, financing and maintenance of railway networks, including some of Europe’s largest high speed rail projects.

Both Eiffage Génie Civil and Eiffage Métal, our structural steel specialist, are engaged on this major project. The latter involves building lots C2 and C3 pf the future high-speed line. This stretch includes 15 viaducts, 5 km of cut and cover, 22 km of road realignment, 81 bridges and crossing structures as well as 30 million cubic metres of earthworks. The contract totals £2,3bn, including the initial design and development phase which are already completed.

-

Grand Paris Express

France - Île-de-France

Grand Paris Express

Eiffage is taking part in developing the Paris region’s future public transport network via the Grand Paris Express, arguably the largest transport project in Europe cumulating €35.6bn of investment. It consists of 200 km of new railway lines (90% being built underground), 68 new interconnected stations and a 100% automatic metro system.

- Line 15 South - Lot T2B (in consortium) includes a 7.2 km tunnel and 3 stations: Saint-Maur - Créteil, Champigny Centre and Bry-Villiers-Champigny.

- Line 16 - Lot 1 includes 19 km of tunnel and 5 stations (Saint-Denis Pleyel, Stade de France, La Courneuve Six-Routes, Le Bourget RER and Le Blanc-Mesnil), 21 ancillary structures, track-laying and catenaries.

- Line 14 South (in consortium) includes a 4 km tunnel and 3 stations (Chevilly Trois-Communes, MIN Porte de Thiais and Pont de Rungis).

- Eole extension – RER Line E includes a 6,1 km tunnel, a station under the Porte Maillot, Bezons flyover (a kilometre-long engineering structure) and rail works (tracks and catenaries).

-

Euralpin Lyon-Turin Tunnel (ELTT)

France & Italy - Lyon to Turin

Euralpin Lyon-Turin Tunnel (ELTT)

ELTT entrusted Eiffage Génie Civil in consortium with the Saint-Martin-La-Porte exploratory structure works. This is an important stage for the cross-border section of over 57 km on the future Lyon-Turin railway line between Saint-Jean-de-Maurienne in Savoie and Susa/Bussoleno in Piedmont. Saint-Martin-La-Porte descent is the first structure starting from the west. This gallery provides access to the future tunnel level 80 km below. At the foot of the descent, the works involve building a 9 km exploratory gallery, excavated by TBM, in the direction of Italy.

TBM Federica was built to excavate Saint-Martin-La-Porte exploratory gallery. Its dimensions are impressive: 138 m long, 11 m in diameter and weighing 2,340 tonnes. It has the power of 7 Formula One engines.

In 2021, Lot 1 of the ELTT was awarded to a joint venture led by Eiffage Genie Civil. The consortium will build the 22km stretch of tunnel between the existing Villarodin-Bourget/Modane tunnel and Italy. The tunnels will be excavated over a 72 month period, using two TBMs to drive the tunnel towards Turin and using traditional methods of mechanical excavation or drill and blast to drive the tunnel towards Lyon.

-

Brittany-Pays de la Loire (BPL) HSL

France - Brittany to Pays de la Loire

Brittany-Pays de la Loire (BPL) HSL

The BPL High Speed Line was constructed as part of a 25-year public-private partnership contract signed in 2011 between RFF and Eiffage. This complex engineering project involved building 182 km of new high speed railway and connections to the conurbations of Le Mans, Laval and Rennes significantly improving access to north western France.

The design and construction of the whole layout was led by Eiffage’s teams and included the crossings of 3 motorways and major watercourses, the provision of new maintenance depots and required the management of many stakeholder interfaces and planning constraints. The works comprised major earthworks, drainage, engineering structures and viaducts; rail track, power and signalling systems; and associated highways, utilities and environmental mitigation works. The new route was tested and commissioned and brought into service just 6 years later in June 2017 starting a period of 19 years of maintenance.

-

Millau Viaduct

France - Millau

Millau Viaduct

Millau Viaduct kept Eiffage Group in the spotlight from the first incremental launch right through to inauguration. It took only three years (exactly) to build the world’s highest viaduct. We were able to keep to this very tight deadline thanks to the steel deck proposed and installed by the Group. Thousands of hours of calculation were needed during the study phase, and no other viaduct had ever been optimized in this way, from the design stage onwards.

Designed by British architect Sir Norman Foster and created by French engineer Michel Virlogeux, this multi-span cable-stayed bridge is 343 metres high and 2,460 metres long, comprising 7 concrete piers and a steel deck. 85,000 m3 of concrete and 36,000 tonnes of steel structure were needed to build the viaduct, which took 14 years of preparation and 3 years of construction, from 2001 to 2004. All Eiffage's branches were involved, as were 600 master craftsmen at the height of the project.

The bridge was inaugurated on 14 December 2004 by French President Jacques Chirac. Eiffage received the International Association for Bridge and Structural Engineering's Outstanding Structure Award in 2006. The IABSE praised the viaduct for being "an elegant, slender bridge ...constructed using an innovative launching procedure”.

-

Highway A3

Germany - Biebelried to Fürth/Erlangen

Highway A3

In 2020, Eiffage Concessions was awarded, in consortium, Germany’s largest public-private partnership (PPP) motorway project. The contract relates to a section of the 76 km long A3 motorway, running between Biebelried and Fürth/Erlangen. The special purpose vehicle, A3 Nordbayern GmbH & Co. KG, will be responsible for the design and work to widen the section from four to six lanes, its operation and maintenance, as well as the partial financing of the services provided.

This project also involves Eiffage Infra-Bau, German subsidiary of Eiffage’s Infrastructures division, which has been assigned together with an external partner to expand the 71-kilometer A3 route. Overall, a total of 91 engineering structures will be built, including 4 large bridges, 22 single-span overpasses in steel-concrete composite construction and 67 underpasses Irritation and noise barriers as well as retaining wall structures. As for the operation and maintenance of the entire 76-kilometer stretch until 2050, winter services, green maintenance, repairs to the route and the repair of accident damage will be carried out by the consortium so that the motorway can be used safely and comfortably by all road users.

-

Highway E18

Norway - Langangen to Rugtvedt

Highway E18

In 2020, Eiffage Génie Civil was designated as the preferred bidder by Nye Veier, a company owned by the Norwegian Ministry of Transport, for a contract covering a section of the E18 motorway. The project covers 7 kilometres of four-lane motorway divided into 2 sections. The first section includes the construction of 4 composite steel concrete viaducts spanning a total length of 1,300 metres. The second section consists mainly of the new Grenland steel structure cable stayed bridge, with a 330 metres main span. The contract also includes 900 meters cumulated long Blafjell tunnels to be excavated and equipped, as well as 3,300 metres cumulated long Kjørholt and Bamble tunnels already excavated and to be equipped.

Eiffage Génie Civil will harness the expertise of several entities of the Group for this project: Eiffage Métal for the construction of Grenland bridge, and Eiffage Route’s GB5® high performance pavement. The Safety Force® innovative application developed by the Group will be used for on-site risk prevention.

-

A65 Motorway

France - Pau to Langon

A65 Motorway

The Langon to Pau motorway, connecting Langon (Gironde) to Pau (Pyrénées-Atlantiques), also known as the A65 and the Autoroute de Gascogne, is a concession project officially inaugurated in December 2010. Aliénor, the concession company for the motorway fully owned by Eiffage since 2021, is responsible for designing, building, financing, maintaining and operating the asset until 2067.

Eiffage Génie Civil built a major part of this 150 km motorway layout involving most of our specialist lines (earthworks, engineering structures, etc.). The road is a model for biodiversity, Eiffage having signed on the actual worksite the "Countdown 2010 for Biodiversity" declaration initiated by the International Union for Conservation of Nature (IUCN), the world’s largest environmental organization. The A65 has brought a range of benefits to the areas along its route, including greater accessibility and new or strengthened activities. In addition, this new motorway link brings Bordeaux closer to the Pyrenean ski resorts, thereby boosting the tourist sector in the central Pyrenees.

-

British Normandy Memorial

France - Caen

British Normandy Memorial

The British Normandy Memorial, inaugurated on June 6, 2021 on the occasion of the 77th anniversary of the D-Day landings, pays tribute to the 22,442 British soldiers who fought for peace in the Battle of Normandy. Commissioned by the Normandy Memorial Trust, created in 2016 to fulfill the veterans' dream of seeing a place commemorating their involvement, this memorial is located overlooking Gold Beach to Ver-sur-Mer in Calvados.

Eiffage Route's teams in Caen are very proud to have participated in the construction of this memorial site. Our teams were chosen to build it as a general contractor, following a public tender in the United Kingdom. They carried out, in their own work, the access roads, platforms, parking lots and pedestrian paths, sanitation and coating works. They also supervised several English-speaking subcontractors suggested by the client. Among them, McConnell & Sons, a Northern Irish company, was responsible for supplying and cutting the stones, as well as engraving the names of the 22,442 soldiers to whom the building pays homage.

-

Limerick Pedestrian Footbridge

Ireland - Limerick

Limerick Pedestrian Footbridge

In 2008, Eiffage Métal carried out the design, manufacture and assembly of the Limerick Bridge in Ireland. This pedestrian footbridge is strategically important in that it links the two campus sites located on both sides of the Shannon River. The deck is supported by two underslung catenary cables and varies in width, offering platforms to be used as resting places or spaces for public art. The five-span structure curves gently above the water on strategically-positioned piers, giving the impression of jumping from pier to pier like stepping stones in the river. The bridge's technical expertise received the Most Beautiful Steel Construction Award in 2008.

- Length: 350 m

- Steel weight: 603 tonnes

- Client: Limerick University

- Architect: Wilkinson Eyre

- Engineering Consultants: ARUP

Marine projects

-

LNG Gorgon

Australia - Gorgon

LNG Gorgon

Through its Eiffage Génie Civil Marine team, specialized in large-scale port and maritime works in France and abroad, Eiffage designed and built turnkey contract for Gorgon LNG (Liquefied Natural Gas) liquefaction plant maritime infrastructure.

- Concrete caissons: 56 units (2 rectangular units, 28 x 23 x 6 m ; 40 circular units, 26 m in diameter x 6 m high; 14 circular units, 20.5 m in diameter x 5 m high)

- Steel modules: 120 units

- Concrete: 60,000 m3

- Steel structure: 34,000 tonnes

- Process piping: 5,100 tonnes

- Solid ballast 150,000 tonnes

- Caisson filling ballast: 24,000 m3

-

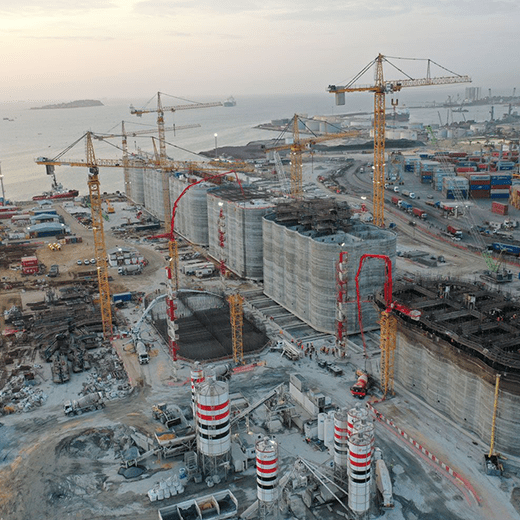

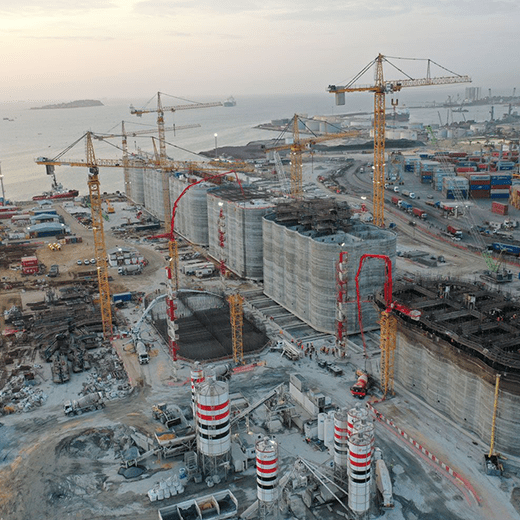

Grand Tortue

Ahmeyim gas terminalAfrica - Mauritania and Senegal

Grand Tortue

Ahmeyim gas terminalIn February 2019, consortium leader Eiffage Génie Civil Marine signed an Engineering, Procurement, Construction and Installation contract with BP for the Grand Tortue/Ahmeyim gas terminal’s marine infrastructure on the maritime borders of Mauritania and Senegal.

This major project involves building offshore marine infrastructure protected by a breakwater dyke, to house a floating natural gas liquefaction plant and enable LNG tankers to berth. The 1.2 km-long breakwater dyke comprises 21 concrete caissons each weighing 16,500 tonnes and manufactured by Eiffage in Dakar (Senegal). It is currently under construction and will be installed at -33 m 10 km off the coast. At the same time, the 2.5 million tonnes of quarry materials required for the underwater dyke foundations supporting the concrete caissons are being produced by Eiffage in Mauritania in a quarry opened specifically for the project.

-

Dredging Portland

United Kingdom - Portland

Dredging Portland

This project consisted of carrying out dredging works at Queens Pier and Outer Coaling Pier at the port of Portland in the UK. Herbosch-Kiere, a leading European marine engineering company owned by Eiffage, dredged approximately 150,000 m³ of sand, clay and rock. We removed contaminated soil and transported it to a designated protected landfill site.

Dredger ALBATROS and split hoppers BEAVER & OTTER were used for these activities.

-

Western Link Liverpool

United Kingdom - Liverpool

Western Link Liverpool

The Western HVDC Link is an offshore high-voltage direct current link in the United Kingdom which runs between Hunterston in West Scotland and Flintshire Bridge in North Wales and is routed to the west of the Isle of Man.

Herbosch-Kiere mobilised multifunctional vessel ATLANTIS to Liverpool in order to repair the offshore electrical cable on the instructions of the Prysmian Group. ATLANTIS was provided with a full onboard cable spread. The water was shallow where the cable lay which meant that the cable was exposed twice a day at low tide and also that the ATLANTIS was beached twice a day.

-

Red Funnel Maintenance Pontoon & Walkway

United Kingdom - Southampton

Red Funnel Maintenance Pontoon & Walkway

After a competitive tendering process in 2020, Herbosch-Kiere Marine Contractors won a contract to replace a maintenance jetty and gangways for Red Funnel Group at the busy Terminal 1 in Southampton. Pontoon SEADEVIL sailed to the UK in June 2021 to carry out the heavy lifting works.

The contract included removing and taking away the existing jetty and access road with all the associated service pipes and manufacturing and installing a new jetty, access road and crane.

-

Al-Zour Refinery – Kuwait

Kuwait - Zour

Al-Zour Refinery – Kuwait

Eiffage Génie Civil is taking part in the Al-Zour Refinery mega-project for Kuwait Petroleum Corporation’s subsidiary KIPIC (Kuwait Integrated Petroleum Industries Company). This project includes three major structures:

- A 1,700 metre jetty for loading ships with sulphur granules produced in the refinery. The jetty will be extended by a wharf and is to carry a 3.6 km conveyor belt linking the refinery with the ship loading towers.

- Sea Island, an offshore platform for loading ships with refined products, located 17 km from the coast and linked to the refinery by an underwater pipeline network. The north and south wharfs linked to the central platform will enable up to 4 ships to be loaded at the same time.

- A service port reclaimed from the sea, comprising a covered area, a berthing facility for support craft, a fuel depot and other infrastructure needed for site operations.

-

London Array cable laying

United Kingdom - London

London Array cable laying

Herbosch-Kiere was awarded a charter contract for the London Array wind farm project by Global Marine (GMSL). The contract involved the installation of 33 kV transmission cables between the turbines and the substations, using our multifunctional vessel ATLANTIS. The project started in September 2011 when we mobilised ATLANTIS to Sheerness.

For the cable installation works, we had to upgrade ATLANTIS to a DP1-certified positioning system. For this particular project, the deck was also adapted by adding a complete cable lay spread.

Energy projects

-

Offshore Wind Project Doggerbank

United Kingdom - Yorkshire coast

Offshore Wind Project Doggerbank

The Dogger Bank Wind Farm is being developed in three phases and is located more than 130km from the Yorkshire coast. Collectively, they will become the world’s largest offshore wind farm when complete, with a combined capacity of 3.6GW, capable of powering 6 million British homes.

Smulders, in consortium with Sif, has been involved with the fabrication and supply of foundations for Dogger Bank A, B and C. Combined, the consortium will have build 277 monopiles and transition pieces for this major offshore wind farm. Specifically, Smulders manufactures secondary steel and assemble, coats and tests fully equipped transition pieces.

-

Beatrice Offshore Wind Farm

Scotland - Outer Moray Firth

Beatrice Offshore Wind Farm

The £2.6bn Beatrice Offshore Windfarm Ltd project has been given the green light for construction in 2016. The project is one of the largest private investments ever made in Scottish infrastructure. It comprises 84 turbines with a total capacity of 588MW. The wind farm is located in the Outer Moray Firth, off the north coast of Scotland and produces enough energy for approximately 470,000 homes.

For this project, Smulders, our international steel construction specialist, built 28 jackets by order of Seaway Heavy Lifting as well as 18 bottom sections by order of Bifab. Every Smulders location had its own share in this project. The final assembly took place at our yard in Newcastle upon Tyne, England.

-

Hinkley Point C

United Kingdom - Hinkley Point

Hinkley Point C

The first new nuclear power station to be built in the UK in over 20 years; Hinkley Point C in Somerset, England will be a twin unit EPR capable of generating 3,260MW of secure, low carbon electricity for around 6 million homes in the UK.

In 2017, Clemessy was awarded the main control room set-up over both units of the power plant. The scope includes:

- Control room & 8 additional associated rooms

- Simulator

- Boxes, panels, pulpits, mimic

- Traywork, cabling, lighting, sockets

- Power & Small Power

- Design, qualifications, procurement, workshop manufacturing and site installation

- Testing & commissioning

Clemessy, an Eiffage Energie Systèmes brand, specializes in the optimisation of industrial processes and offer innovative solutions for the most demanding industries, from nuclear, aeronautics and space to the automotive, pharmaceutical, petrochemicals or metallurgy.

-

Fessenheim Power Plant – Electricity Generation / Maintenance

France - Fessenheim

Fessenheim Power Plant – Electricity Generation / Maintenance

EDF awarded Clemessy a preventive and corrective maintenance contract for the Fessenheim nuclear power plant in France.

The contract involves performance obligations to ensure the availability of the equipment relating to the protection of the site.

Several levels of maintenance (levels 1 to 4).- 6-year contract (4 years and 2 years option).

- Preventive and unscheduled maintenance of all the electrical safety installations (ESI).*

- Whole scope, site protection; camera, gantry, gate, badge readers, impact cable, concertina etc.

- On-call duty, document monitoring, capitalisation of feedback, technical assessment.